Future is Electric

WHO WE ARE

Precise, Unique & Improved

Nimble Electric’s motion control response has only improved with age, apparent with the lines of recommendation we’ve gathered over the years. An invaluable subsidiary of UCAM, Nimble Electric has supplied top-of-the-line torque motors to manufacturers since 2013, with staggering improvements in its product range with each iteration. The gamut of precision motors includes direct drives, high precision antenna-testing Fixtures & tethered Multi copters, each of these solutions backed by tireless product support teams ready with a battalion of engineers and formidable stock of spares.

15

TEAM MEMBERS

10

YEARS OF EXPERIENCE

20+

HAPPY CLIENTS

15+

SOLUTIONS

INFRASTRUCTURE

Design, Production & Quality Assurance

The longest distance between two breakdown points is most likely covered by a Nimble Electric motor. It’s not surprising, given the brushless and gearless nature of our torque motor designs.

Tested rigorously and refined continuously, our motors showcase phenomenal durability and performance, sturdy construction and optimized heat dissipation.

Research & Development Facility

Nimble Electric’s prolific R&D department is the epicenter of motor refinement, constantly innovating and developing customer-focused cost-effective solutions. Like our motors, our evolution, performance improvements and innovation never stay still.

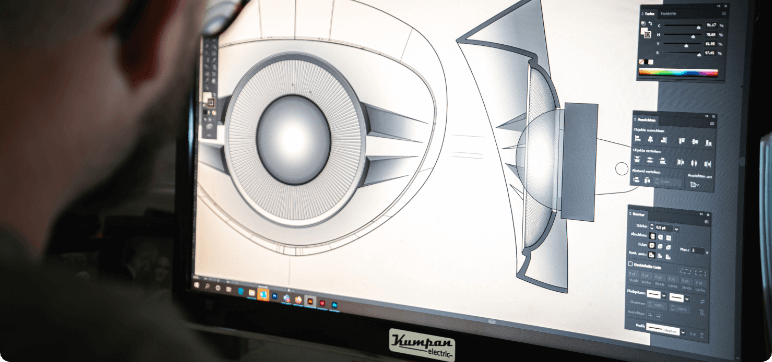

Design Facility

Nimble Electric’s dedicated vibrant, in-house design department banks on unfettered engineering intuition, supplemented by high-end software and design tools in product design to perform FEA Analysis and refinement in existing products as well as the development of breakthrough offerings.

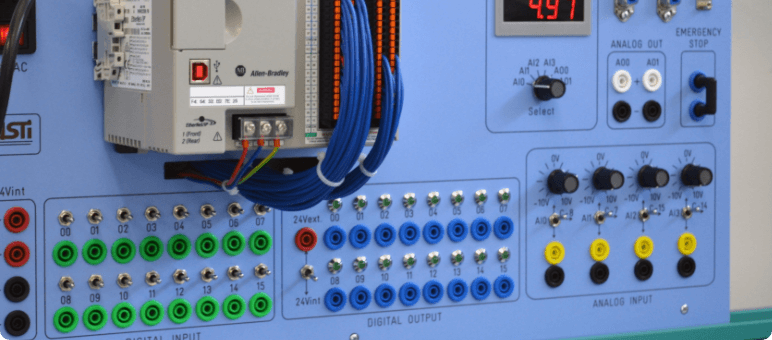

Testing facility

Equipped with regularly upgraded technology instruments, Nimble’s quality labs perform rigorous checks on performance and durability. Insulation, harmonics, torque and speed characteristics being just a few of the parameters checked at micro-fine levels.

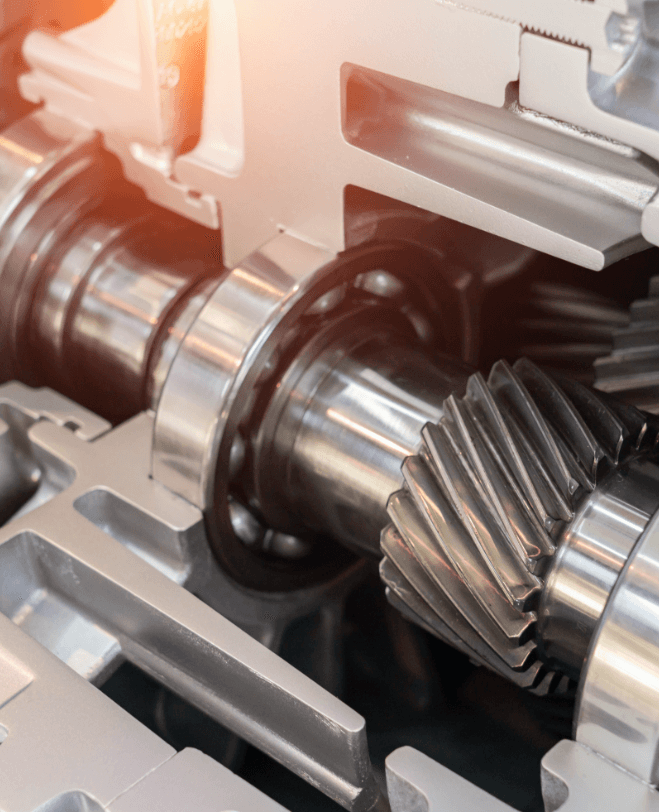

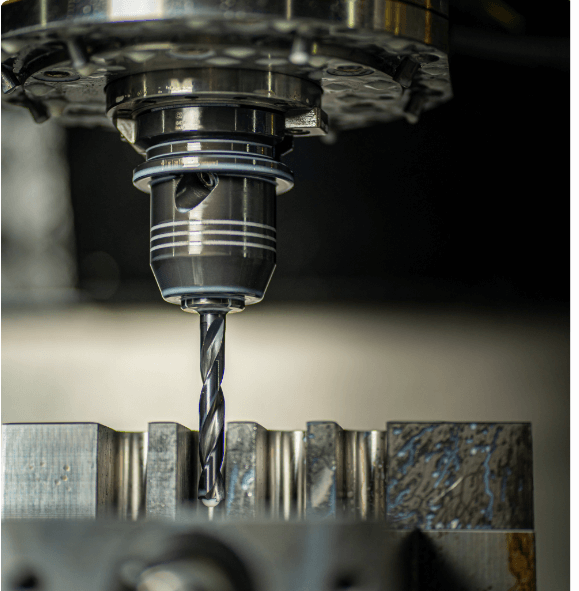

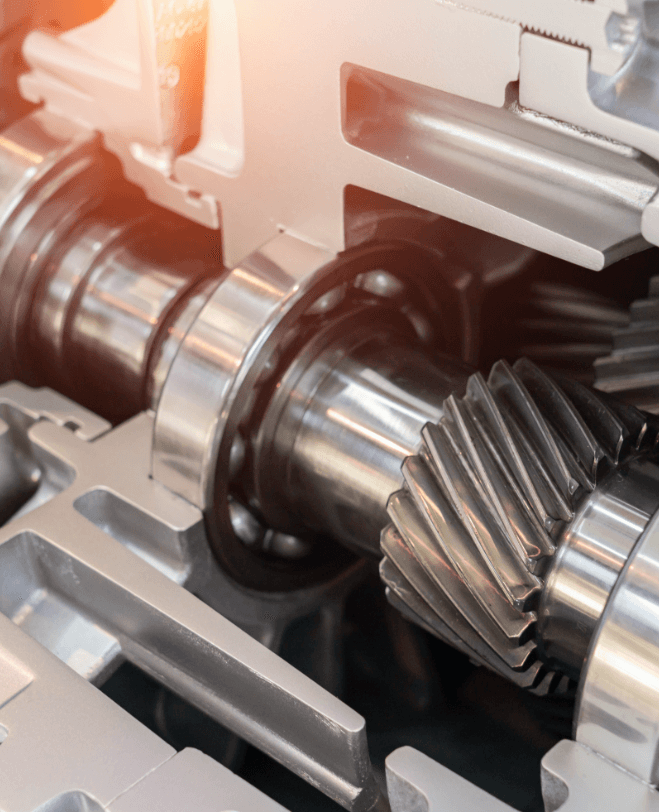

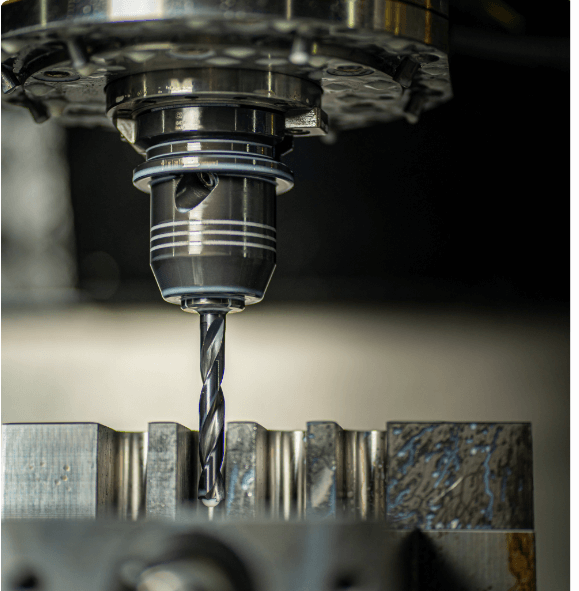

Manufacturing facility

Nimble Electric’s state-of-the-art machining and assembly sections ensure each motor is dimensionally precise. Its winding section optimizes copper windings in every motor, vacuum impregnation and encapsulation units imparting superlative performance and mechanical ruggedness.

Product development methodology

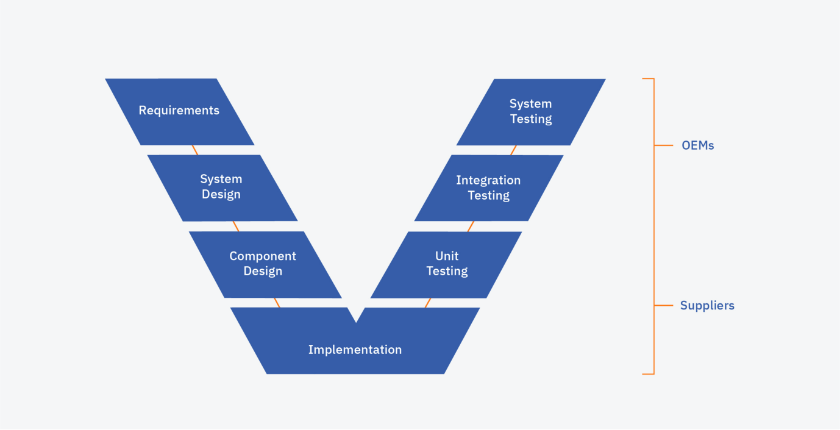

We rely on the V-model process, better known as the Verification and Validation Model. While following a sequential design process akin to the Waterfall model, we perform testing of the device after planning it parallel to its corresponding stage in design.

INFRASTRUCTURE

Design, Production & Quality Assurance

The longest distance between two breakdown points is most likely covered by a Nimble Electric motor. It’s not surprising, given the brushless and gearless nature of our torque motor designs.

Tested rigorously and refined continuously, our motors showcase phenomenal durability and performance, sturdy construction and optimized heat dissipation.

Nimble Electric’s prolific R&D department is the epicenter of motor refinement, constantly innovating and developing customer-focused cost-effective solutions. Like our motors, our evolution, performance improvements and innovation never stay still.

Nimble Electric’s dedicated vibrant, in-house design department banks on unfettered engineering intuition, supplemented by high-end software and design tools in product design to perform FEA Analysis and refinement in existing products as well as the development of breakthrough offerings.

Equipped with regularly upgraded technology instruments, Nimble’s quality labs perform rigorous checks on performance and durability. Insulation, harmonics, torque and speed characteristics being just a few of the parameters checked at micro-fine levels.

Nimble Electric’s state-of-the-art machining and assembly sections ensure each motor is dimensionally precise. Its winding section optimizes copper windings in every motor, vacuum impregnation and encapsulation units imparting superlative performance and mechanical ruggedness.

We rely on the V-model process, better known as the Verification and Validation Model. While following a sequential design process akin to the Waterfall model, we perform testing of the device after planning it parallel to its corresponding stage in design.

[logo-showcase id=”981″ title=”Clients”]

Testimonials

Nimble Electric in the News

NOVEMBER 20, 2021

TOP entrepreneurs, BUSINESS TRANSFORMED THROUGH TECHNOLOgy…

NOVEMBER 20, 2021

Best Metal Cutting Brand Award 2019 – UCAM Pvt Ltd.

The award for the best metal cutting brand was given to UCAM Pvt. Ltd for thier extensive efforts.

NOVEMBER 20, 2021

Indian Machine Tool Manufacturers Association (IMTMA)…

NOVEMBER 20, 2021

TOP entrepreneurs, BUSINESS TRANSFORMED THROUGH TECHNOLOgy…

The award for the best metal cutting brand was given to UCAM Pvt. Ltd for thier extensive efforts.

NOVEMBER 20, 2021

Best Metal Cutting Brand Award 2019 – UCAM Pvt Ltd.

The award for the best metal cutting brand was given to UCAM Pvt. Ltd for thier extensive efforts.

NOVEMBER 20, 2021

Indian Machine Tool Manufacturers Association (IMTMA)…

The award for the best metal cutting brand was given to UCAM Pvt. Ltd for thier extensive efforts.

Our Business Verticals

The most preferred name in the Indian machine tool industry, UCAM dwells at the frontier of CNC rotary table and accessory development.

A UCAM offshoot committed to the design and manufacturer of precision 6 Axis CNC gear cutting machines.

We distribute globally renowned products such as couplings, torque limiters, and industrial couplings from R+W – Germany.